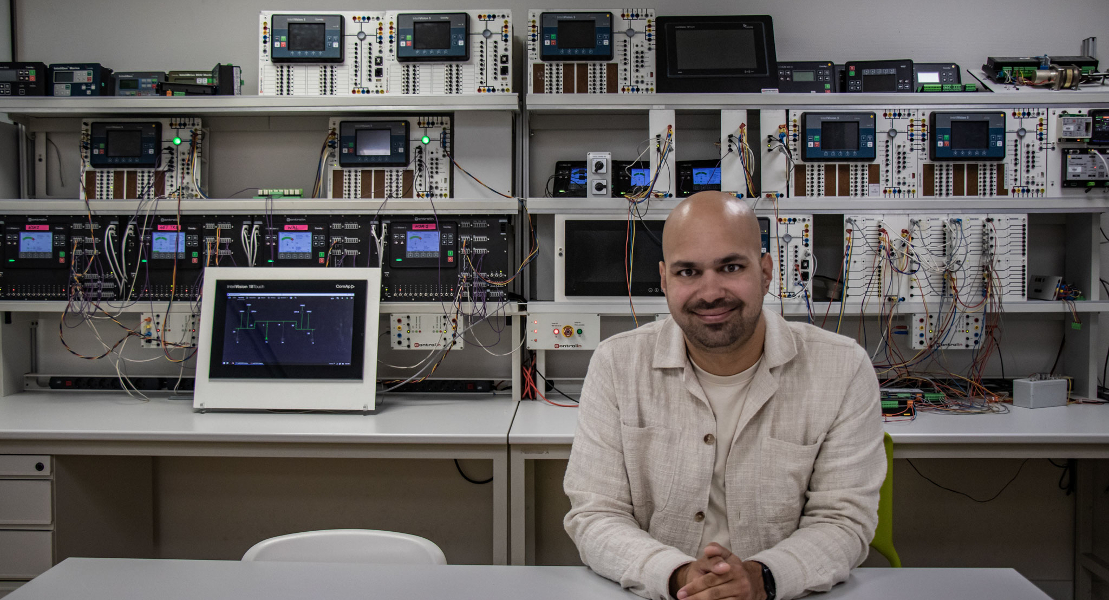

Controlin launches SKD flow, a system that measures and monitors all energy flows in buildings in a dashboard. Recently, devices can even be controlled automatically based on the data. But how did the company that originated in analog meters and the power management of large emergency generators in data centers and hospitals come to release a fine-tuned energy management system that can eventually control a building's lights, shutters and climate and grow into a complete building automation system? Actually, that has grown quite logically, says Andy van Maaren, marketing manager of Controlin.

Controlin began as a supplier of analog meters for harsh environments, such as shipping. There is still an employee in the building modifying these meters. 'They are meters for current, KW, Voltage, frequency and so on. For each unit you have a separate meter. In the environments where they are used, it is important that you can see at a glance what is going on without having to think about it. Then analog meters are better than digital ones.'

Analog meters

So the meter, or sensor is Controlin's origin, and the fact that measuring is knowing, and that you can take the right action from there is deeply ingrained in the company. With that, it has since entered other markets. The next step was controlling large emergency generators for data centers and hospitals, for example. In that environment, too, it is important that information is immediately converted into a host of actions. If the power fails, the emergency generator must be started up immediately.

That seems simple, but it is disappointing. 'Then you have to start distributing the power smartly, and that all has to be automatic,' Van Maaren says. 'First of all, for example, electricity has to go to preferred departments, such as the operating rooms and the incubators. Because that's where lives are at stake. The waiting rooms can wait. That is a way of thinking that is completely in our DNA and that we have also put into SKD flow.'

Monitoring of energy

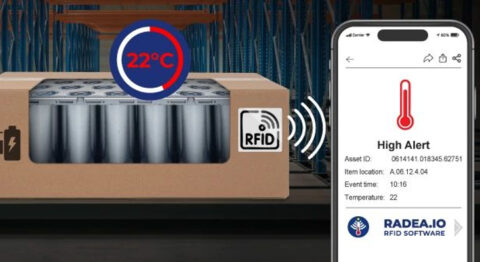

SKD flow is also about converting the data from sensors into information and ultimately into automatic actions. Only this involves collecting information about building energy flows. The first step in this is still the sensors from SKD flow gateway, the solution in the context of "measuring is knowing. Meters are installed that collect data on, for example, the energy generated by the solar panels and the energy consumption of the various installations. The information from that data is simply read out locally, or exported to a .CSV file.

Dashboard

If you want to start actively monitoring energy flows, it is convenient if the data is presented in a dashboard. You can then easily scale up to SKD flow monitoring. This displays all the meters in a map. This also allows you as a company to easily demonstrate, for example, that the total energy consumption is decreasing. But you can also see where how much energy is being consumed and you can predict energy consumption in the future so that you can take action accordingly.

Of course, Controlin then had to provide a good application with which to easily access the information. They developed the software that Controlin uses for this purpose themselves. 'At first we thought we could do it with the current product portfolio we use for the generators,' says developer Chris. 'But that wasn't easy to use, so we started writing the software ourselves. Then you can also structure it however you want.'

Very important here is that they chose a communication protocol that is very broad and open and that they did not limit themselves to that one protocol. All meters and sensors from all manufacturers should be able to work with the system, so that all the information of the building can come together in one place.

Partner in energy management and building automation

Because Controlin made the system entirely their own, they can set it up however they want. This ensures the flexibility to add functionality themselves if customers request it. Listening to customers is a high priority anyway, says Van Maaren. 'We don't want to be a supplier so much as a collaborative partner for energy management and building automation.'

Hence, the third step of the system was recently introduced. From SKD flow monitoring, you can now easily scale up to SKD flow automation, which is aimed at automatically driving and controlling processes. This allows you to start with load balancing and peakshaving, for example. Something that with the current state of energy supply will certainly be on customers' wish lists.