Construction company Heijmans set a number of goals in terms of sustainability in 2018. For example, it wanted to be CO2 neutral by 2023. That deadline is almost here, so it's time to take stock. "We were very ambitious. But with the idea that we would set a trend, even if we didn't achieve everything. With our ambitions we also wanted to get others on board,' says director of sustainable development Robert Koolen.

Heijmans' sustainability goals must be seen in the bigger picture of the entire 2018-2023 strategy, Robert says. That strategy consisted of three pillars: improve, smarten up and make sustainable. 'Improving is about quality and safety, that is of course the basis. Maybe it's self-evident, but you shouldn't forget those and you have to flesh them out. We either build safely or we don't.'

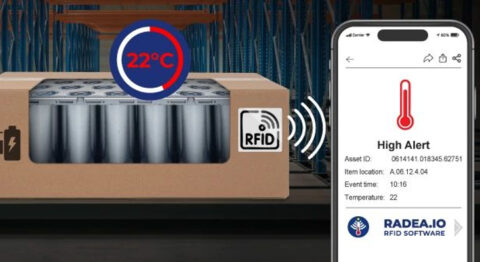

Smartening up is about digitalization and manufacturing technology. 'For example, we took over a wood frame construction plant and started expanding it.' In addition, for example, a lot of equipment is equipped with sensors. These show where something is, how long it is used. But also, for example, how long it is idling. 'With that information you can start optimizing, and that in turn has an impact on sustainability.'

Three programs for sustainability

Sustainability in turn has three programs: energy transition, material transition and spatial transition. The spatial transition has to do with climate adaptation and biodiversity. 'How do you deal with the consequences of climate change. It's getting wetter, hotter and there are more storms. You then talk about dike reinforcement and water collection, for example. But also about greenery in the environment.'

In material transformation, you're talking about circularity. 'At the design stage you already look at how you can use as little material as possible, and that material must also be detachable and biobased as much as possible. Our new timber frame building factory in Heerenveen also helps with that, of course.'

The most ambitious was the strategy for energy transition. By 2023 - so now - Heijmans wanted to be CO2 neutral in terms of direct emissions. 'We didn't quite achieve that,' Robert says, 'but great strides have been made.' He explains that there are four knobs to turn. First, you have the offices. There are now solar panels on them, there is LED lighting everywhere and they are A-label. The second knob is mobility, the people who go from A to B. From January, all lease cars will be electric and the vans will also be electric as standard.

The equipment

But it gets really complicated when it comes to electrification of the equipment that Heijmans uses for its projects. That's not so bad when it comes to small equipment, such as forklifts and rammers. 'Those are easy to make electric, but it's different with asphalt pavers and rollers, for example.'

Yet Heijmans is also electrifying those asphalt pavers and rollers. They just have to initiate this themselves. They are working with a number of parties who are good at this. 'We converted the rollers together with those parties, and now we have bought an asphalt paver that we are electrifying,' says Robert. 'Equipment management is really an important party in this. HMB is making great strides right now.'

The construction site

Finally, there are the construction sites. To make those sustainable, energy is generated with solar panels, for example. But there must also be charging points for all electric equipment. 'In the city this is usually not such a problem, but outside you have to apply for a connection, and then you're a year and a half away,' says Robert.

Or you have to go with battery packs for small connections. Small battery packs have to be charged overnight and put back on the construction site in the morning. But you also need very large batteries for the big equipment. Then again, you have to have two of those, one being charged while you use the other.

"That's interesting," Robert thinks, "because it also does something to your planning. You used to just say, 'I need equipment,' but now you also have to think about how that equipment gets its energy." So energy supply becomes an important planning component. That's really a change. And just like any other line of planning, it also impacts the rest of the planning.'

The principals

Heijmans itself is taking good steps, but without clients the company is nothing, of course. So there must also be movement on the customer side if the transition is to be successful. Customers are asking for electric vehicles. That is fine, of course, but it is also more expensive. Budgets are still set in the old world and people are still used to that. So you sometimes have to re-enter that discussion.'

Major clients like RWS and ProRail are fortunately thinking along, Robert points out. 'They understand very well the importance of this. Emission-free equipment means less nitrogen. And less nitrogen emission means you can allow plans to go ahead that would otherwise come to a standstill because of the nitrogen rules.'

The same applies to timber construction, for example, which also releases fewer emissions. Heijmans has made versions of all standard homes based on HSB. Because HSB is prefabricated in the factory in Heerenveen, the houses only need to be assembled on site. Moreover, wood is much lighter than traditional material. Therefore, less and less heavy machinery is needed on the construction site, which saves a lot of emissions.

The role of government

The government needs to play a greater role in the area of sustainability, Robert believes. For example, subsidies could be much more efficient. 'There is now a subsidy pot for the purchase of electric equipment, but quite a bit remains out of the picture. All the logistical adjustments are not in the price of the equipment, but that is where a large part of the costs are.'

The government can also play a greater role in setting standards for what we find acceptable, he argues. And in standardization, because the market is very fragmented. In the area of emissions, there has just been the Clean and Emission-Free Building Covenant. 'It's still a covenant and not a regulation, but it puts a floor in the market and so everyone has to get on board,' Robert observes. 'With all the investments we've already made, we personally think we can achieve the most ambitious path relatively easily.'

Toward the future

Now that it is 2023, it is also time for a new strategy that runs until 2030. Sustainability also plays an important role in this, Robert points out. In it, the healthy living environment gets even more focus, he says. 'Water is becoming a more important issue. We have solutions for that, such as water collection, adapted sewer systems, more greenery in cities, water collection on buildings. In neighborhoods we design there is more room for collection, such as wadis, but we also apply open paving.'

Furthermore, the focus is shifting from direct emissions to indirect emissions. 'That's about the choice of materials and the choice of suppliers and partners. I think this is a nice continuation of our existing strategy. We first put our own household in order, and now we are going to influence our indirect household.'

So when choosing a brick, Heijmans will not only look at the size, color and quality, but also at the CO2 emissions during production. 'We already did that, but now we are going to see if we can link real numbers and targets to that. Then it is important to get all the information around such a product above what is there. Within our company, but also from our suppliers. Reliability, openness and transparency throughout the chain then becomes important.'

The more transparent the supplier, the more credible the sustainability claims and thus the more interesting that supplier becomes for Heijmans. 'That game is going to be played a lot in the coming period,' Robert concludes.