Heat pumps are slowly becoming the standard for heating. The message from the government to make them (i.e. the hybrid variant) compulsory when replacing a natural gas-fired boiler, as well as the high gas prices last winter, have given the heat pump a big boost. There are now hundreds of brands/types for sale and the range is still growing. In this regard, what are some interesting developments?

Heating and cooling

Heating a home used to be enough, but due to climate change there is a very clear need to cool homes in addition to a demand for heat. The fact that we are increasingly insulating houses and buildings and that ventilation air is kept at a better temperature by means of heat recovery also increases that need. A heat pump can meet both heat and cold demand, and so both functionalities are considered when purchasing a heat pump. For summer cooling, it is important to know the maximum output at high outdoor air temperatures, but also to understand energy consumption.

Decibels

A hot topic with heat pumps is noise, or decibels. Manufacturers are aware that noise can really be a dealbreaker. The change in the Building Code also encourages development to produce ever quieter appliances. The rule now is that noise at the property boundary may be 40 dB at night and 45 dB during the day. The reduction in noise is usually achieved by better fans, and often the evaporator area is also increased. If homeowners or neighbors still experience noise nuisance, it is possible to place a sound-absorbing casing over the outdoor unit.

Natural refrigerants

Developments in refrigerants also continue. Synthetic refrigerants have a great impact on the environment and are therefore being phased out. There is plenty of experimentation with natural refrigerants. Examples of such refrigerants include ammonia, carbon dioxide, propane, butane or pentane. They all have their own specifications and capabilities.

There are already several heat pumps on the market that run on R-290 (propane). That has a very low GWP but a high COP. The temperature range is high (the critical temperature is 96.7 ⚬C), the price is low and it is readily available. The intention is to use only natural refrigerants in the future. By the way, there are manufacturers engaged in building heat pumps that run without refrigerant.

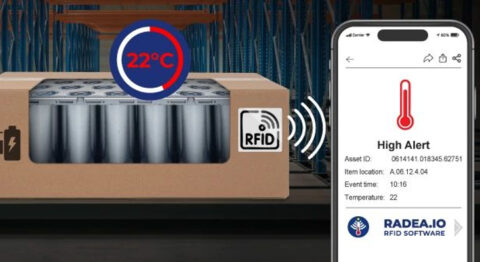

Energy management system

An energy management system (EMS) can control a heat pump on various parameters, such as the price of electricity from the grid, or the availability of green, self-generated electricity. For example, it may be smart to heat the buffer tank for domestic hot water at a certain time, or not yet. The control technology is thus used with the aim of making the heat pump operate as efficiently as possible. The optimal situation is always: maximum comfort at minimum cost. An EMS also plays a role when it comes to control, monitoring and predictive maintenance. The rise of the EMS is really something for installers to keep an eye on and delve into.

Ready for all-electric

The use of the refrigerant propane (R-290), among others, allows heat pumps to have an increasingly higher temperature range. This brings the input temperature to the same level as that of a natural gas-fired boiler.

Therefore, there is an increase in the supply of all-electric-ready concepts, or, in other words, ready for all-electric. A higher capacity heat pump is then first coupled to a boiler as a hybrid. At a later time, for example after installing insulation or modifying the delivery system, that combination can then be relatively easily modified into an all-electric air-to-water setup.

Neighborhood-level solutions

In the ambition to heat the built environment without natural gas, more and more is also being done on a collective level. When new apartment buildings are being built, apartments are being sustainably renovated, or an existing neighborhood is getting rid of natural gas, it is obvious that a collective solution will be chosen.

So rather than each household having its own individual heat pump, it is connected to a central facility in the apartment complex, street or neighborhood. This could be a heat network, but a collective heat pump is also an option. There are always several ways to realize a collective heat supply. It very much depends on the situation on site.

Faster installation

The energy transition requires speed and large numbers. The time required to install a heat pump does not cooperate in this. Manufacturers do try to make appliances simpler, more "plug & play," but "plug in & go" is really not possible as far as heat pumps are concerned. But product innovations may be able to cut the time it takes now in half. Today, a simple installation usually takes one to two days. A complex installation requires considerably more time. That can be as much as five working days, with some of that time then required for modification to the home and/or the delivery system.

To install a monoblock heat pump, an installer does not need an F-gas certificate, which makes installation easier. Prefabrication is also quicker, such as in the form of skids that are assembled as far as possible in a workshop, after which the assembly can be lifted into a new building.

On the roof, or in the roof

Noise and space considerations have caused new types of heat pumps to be developed. So there are heat pumps for sale with a completely different appearance. The shape allows a different installation location, such as the so-called chimney model. The outside part then has the "look" of a chimney and is thus located outside the house. This saves a lot of space, and an additional advantage is that any noise is simply blown away.

The indoor unit of the system sits directly under the roof of the house. This is advantageous because, in principle, the outdoor unit should be placed as close as possible to the indoor unit. Then the heat does not have to travel a long distance, as that always comes at the expense of efficiency. These ready-made roof units are becoming increasingly popular. Flat, prefabricated INroof constructions are also on the rise.